The TSC trolley measures track geometry. The measurement

results include values of track gauge, cant, horizontal and vertical irregularities along with the calculated gradient and twist parameters.

Track measurement

Back to the listTRACK CART FOR TRACK GEOMETRY AND RAIL WEAR MEASUREMENT

LASER AND INERTIAL TECHNOLOGY TO MEASURE TRACK GEOMETRY AND RAIL WEAR

The Trackscan Cadd-e can measure continuously at speeds up to 16 km/h. The results are directly displayed on the operators monitor and automatically saved to memory. A precise inertial technolgy measures simultaneously for both rail courses. The supplied Dari® software allows for analysing the measurement results from any computer and can generate different reports.

The device meets requirements of the EN 13848 - 4 standard

The measurement data is displayed on a weatherresistant and ruggedised PC based control unit providing the operator with comfortable working conditions at night (backlight), day (visibility even in direct sunlight) and with comfortable touch screen display.

The measurement data is displayed on a weatherresistant and ruggedised PC based control unit providing the operator with comfortable working conditions at night (backlight), day (visibility even in direct sunlight) and with comfortable touch screen display.

Built-in functionality allows the user to compare measurements taken at different periods of time. All measurements are presented in the form of graphs with selected parameters exceeding the specified tolerance, there are also icons showing track defects observed by trolley operators during measurements. Track geometry reports can be saved in Word, Excel, PDF, CSV formats. The software enables exporting data and printing reports. The standard version of the software provides capabilities of generating reports for:

- Charting measurement data,

- The report numerical measurement results,

- The report defects,

-

The report performance indicators.

By saving the GPS position, measurement results can be displayed on maps.

By saving the GPS position, measurement results can be displayed on maps.The system allows the measurement of the rail head cross-section. Measured results are automatically analyzed and parameters of wear are automatically calculated. The results of these calculations are presented in the form of graphs.

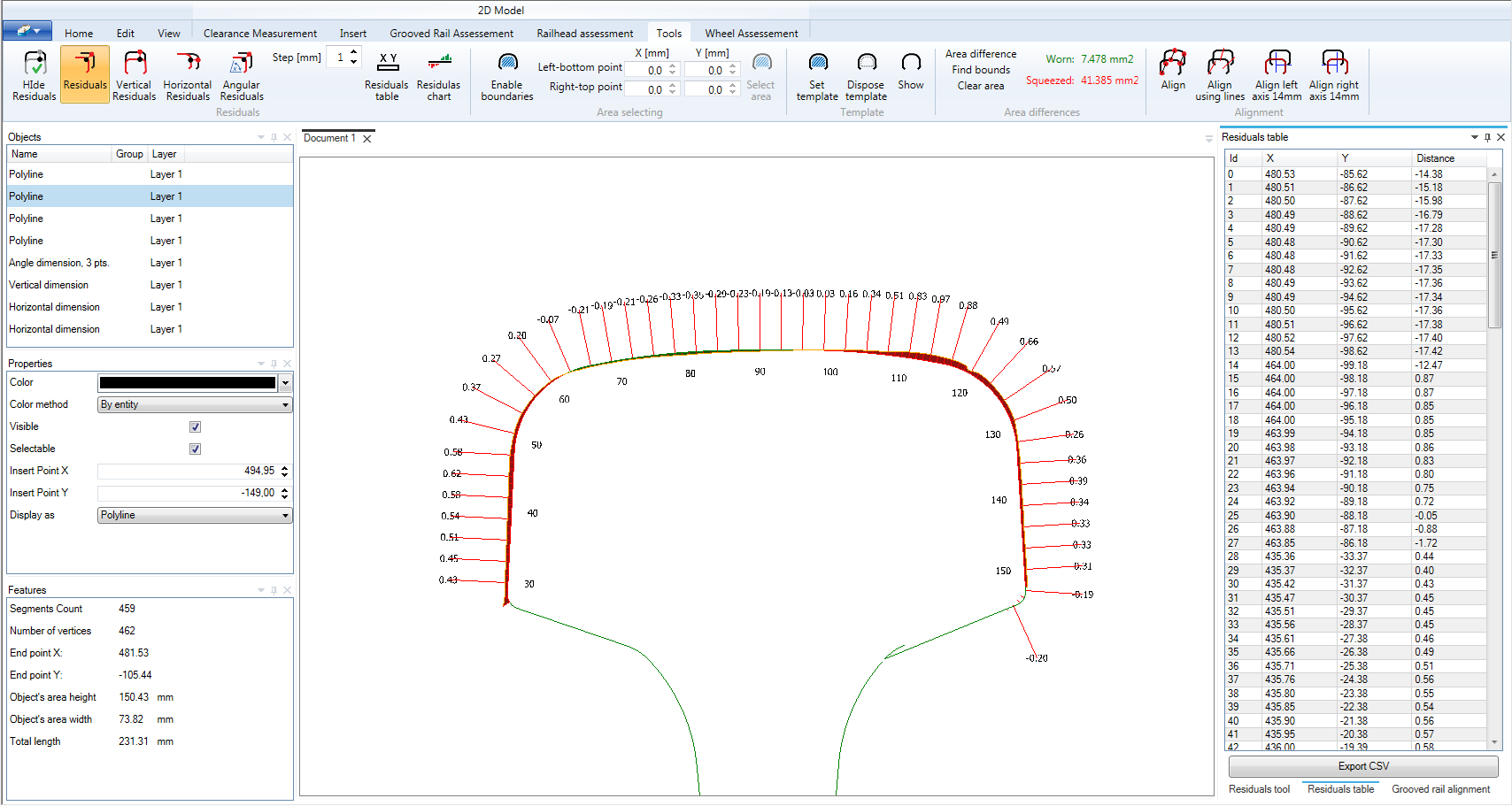

The software makes it possible to perform detailed analysis of selected cross-sections and compare them with nominal profiles. Results of railhead wear analyzes can be printed as reports or saved to DXF files.

Screenshot of the PC measurement data analysis and reporting software delivered with the Trackscan Cadd-e

An example of automatic calculation of rail head wear

Contents:

- Trackscan Cadd-e self driving cart

- Specialized laptop + software

- A set of batteries with chargers

- Measuring system calibrator

- Trackgauge Solar device for cant zeroing before measurement

- Dari® Software for data analysis, 1 licence

Benefits:

- Geolocation of point measurement using GPS on board

- Laser measurement heads enable accurate measurement of rail profiles and determination of rail head wear parameters

- Results of visual track inspection can be recorded while measuring

- Additional software module to the analysis of rail profiles

- Measurement results independent of environmental conditions

- The included Dari® software for data analysis allows for additional export of measured data to MS Excel and MS Word , as well as PDF, DXF, CSV formats

Specifications

| Railhead cross sections | Accuracy of mapping: ±0.3 mm |

| Track gauge | Accuracy: ±1 mm |

| Measurement range: -15 … +50 mm | |

| Cant | Accuracy: ±1,5 mm |

| Measurement range: ±225 mm | |

| Horizontal irregularities (Alignment) | Accuracy: ±1,5 mm / 10 m |

| Measurement range: ±50 mm | |

| Vertical irregularities (Longitudinal) | Accuracy: ±1 mm / 10 m |

| Measurement range: ±50 mm | |

| Calculated parameters | |

| Twist | Accuracy: ±3 mm |

| Gradient | Accuracy: ±1,0 mm |

| Railhead wear | Accuracy of mapping: ±0.3 mm |

| Measuring increment | 0.25 m |

| Types of rails | Vignol or groove |

| Dimensions (L x H x W) for 1435 mm track | 2860 x 1600 x 1620 mm |

| Weight (standard version for 1435 mm track) | 280 kg |

| Memory capacity | Up to 56 000 km |

| Operation range with one battery | Up to 60 km |

| Resolution | 0.1 mm |

| Satellite location (GPS) | Accuracy: ±5 mm |

| Operating conditions | Temperature: -20 … +45 °C |

| Humidity: 15 …85 %, no condensation | |

| Nominal track gauge | 1435 mm, other on request |