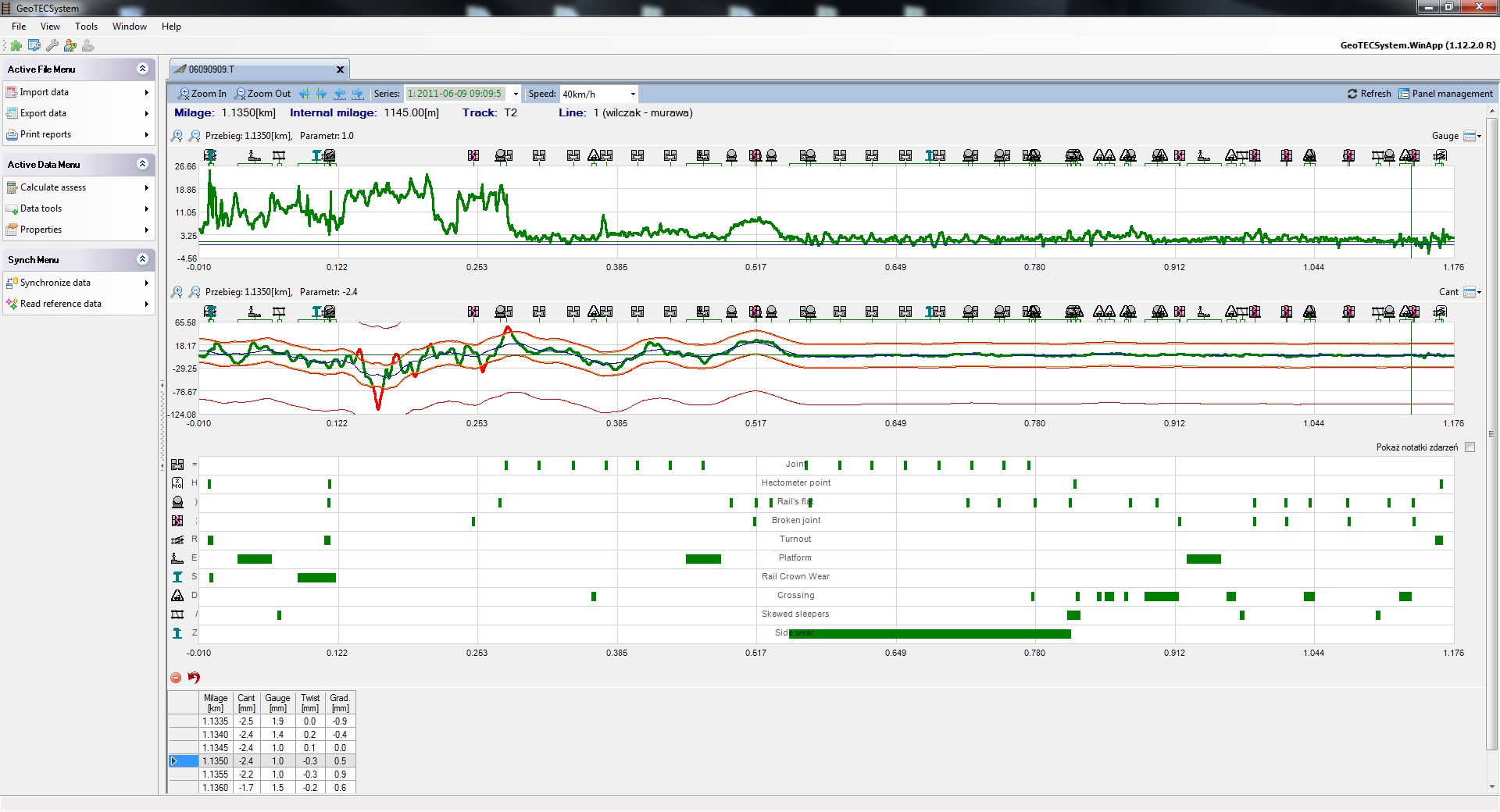

The TSC trolley measures track geometry. The measurement

results include values of track gauge, cant, horizontal and vertical irregularities along with the calculated gradient and twist parameters.

Track measurement

Back to the listTRACKGAUGE DIGITAL

SMART MEASUREMENT OF TRACK AND SWITCH GEOMETRY

The Trackgauge Digital measurement device measures track and switch geometry using an application on a mobile Android™ device. The measurement data can be viewed instantly. The included Dari® software allows further analysis and reporting.

The measurement data is displayed immediately, additional information on the infrastructure, including the results of the visual inspection, is recorded in a digital format. The measurement reports are created on the smartphone by the GOLDSCHMIDT DIGITAL APP.

The Trackgauge Digital measurement device measures track and switch geometry using an application on a mobile Android™ device. The measurement data can be viewed instantly. The included Dari® software allows further analysis and reporting.

The measurement data is displayed immediately, additional information on the infrastructure, including the results of the visual inspection, is recorded in a digital format. The measurement reports are created on the smartphone by the GOLDSCHMIDT DIGITAL APP.

The gauge is supplied with the Dari® software (for PCs) enabling, among other things, the graphic presentation and comparison of measurement results as well as the printing of measurement reports. Measurement results are also available in the tabular form containing track defect locations. Measurement data can be exported in MS Word, MS Excel and PDF formats.

Screenshot of the PC measurement data analysis and reporting software delivered with the TGD

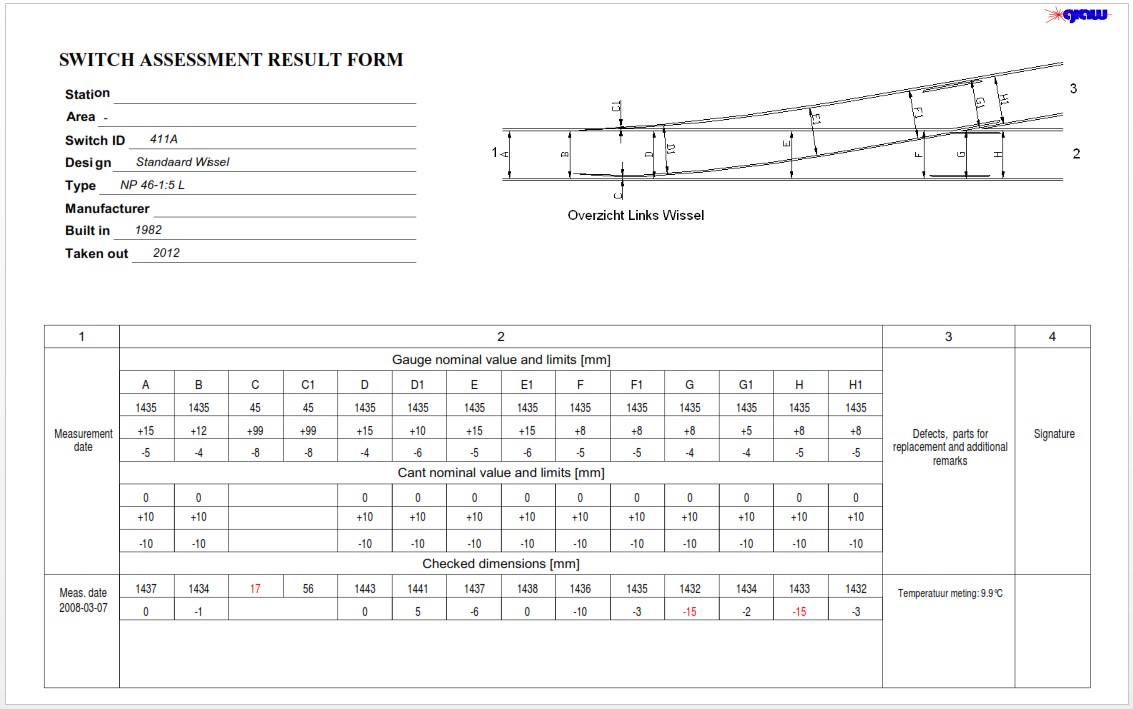

In addition, the turnout module of the GeoTEC System software can be used to modify and create new sets of characteristic points, including information about measured parameters, nominal values and allowed tolerances in relation to various types of turnouts.

The Turnout Measurement Report

Contents:

- Trackgauge Digital device (mobile device not included)

- Charger

- Transport box

- Trackgauge Digital App (Android™

- Dari® software for data analysis, 1 licence

Benefits:

- Easy operation of the device during measurements and transport

- Measurement of switches in accordance with previously created definitions

- Measurement results independent of environmental conditions

- Reports in PDF format available immediately after the measurement

- Available as standard for the 1435 mm track gauge, other track gauges are available on request

- The included Dari® software for data analysis allows for additional export of measured data to MS Excel and MS Word as well as PDF, DXF, CSV formats

Specifications

| Track Gauge | Accuracy: ±0.3 mm |

| Measurement range: -20 ... +50 mm | |

| Cant | Accuracy: ±0.5 mm |

| Measurement range: ±250 mm | |

| Left / right flangeways (groove) | Accuracy: ±0.4 mm |

| Measurement range: 26 ... 200 mm | |

| Twist (calculated) | Accuracy: ±1 mm |

| Gradient (calculated) | Accuracy: ±0.6 mm |

| Measuring increment | 0.5 m; 1.0 m; 5.0 m; 10.0 m |

| Types of rails | Vignol or groove |

| Dimensions (L x H x W) for 1435 mm track | 1600 x 120 x 140 mm |

| Weight (standard version for 1435 mm track) | 2.4 kg |

| Memory capacity | 8 000 measurement files |

| Operating time | Up to 10 h |

| Operating conditions | Temperature: -20 … +45 ºC |

| Humidity: 15 … 85 %, no condensation |