The TSC trolley measures track geometry. The measurement

results include values of track gauge, cant, horizontal and vertical irregularities along with the calculated gradient and twist parameters.

Track measurement

Back to the listTRACKSCAN PROFILE

LASER TECHNOLOGY FOR CONTINUOUS MEASUREMENT OF TRACK GEOMETRY

Goldschmidt´s Trackscan Profile is a trolley equiped with advanced laser measurement moduls. This allows for the measurement of track geometry as well as the rail cross profile. The results are directly displayed on the operators monitor and automatically saved to memory. The supplied Dari® software allows for analyzing the measurement results from any computer and can generate different reports.

The TSP trolley meets the requirements of the EN 13848-4 standard. Measurement results generated by the trolley are consistent with the requirements of the Polish Railway Lines (PKP PLK).

The trolley is provided with a colourful backlit display and a comfortable keyboard (typical of other GRAW products). Measurement results and information about exceedings of allowed values are perfectly visible even at night. Dedicated keys of typical defects facilitate the recording and annotation of cracks in welds or rails, missing bolts, sleepers requiring replacement, etc.

Goldschmidt´s Trackscan Profile is a trolley equiped with advanced laser measurement moduls. This allows for the measurement of track geometry as well as the rail cross profile. The results are directly displayed on the operators monitor and automatically saved to memory. The supplied Dari® software allows for analyzing the measurement results from any computer and can generate different reports.

The TSP trolley meets the requirements of the EN 13848-4 standard. Measurement results generated by the trolley are consistent with the requirements of the Polish Railway Lines (PKP PLK).

The trolley is provided with a colourful backlit display and a comfortable keyboard (typical of other GRAW products). Measurement results and information about exceedings of allowed values are perfectly visible even at night. Dedicated keys of typical defects facilitate the recording and annotation of cracks in welds or rails, missing bolts, sleepers requiring replacement, etc.

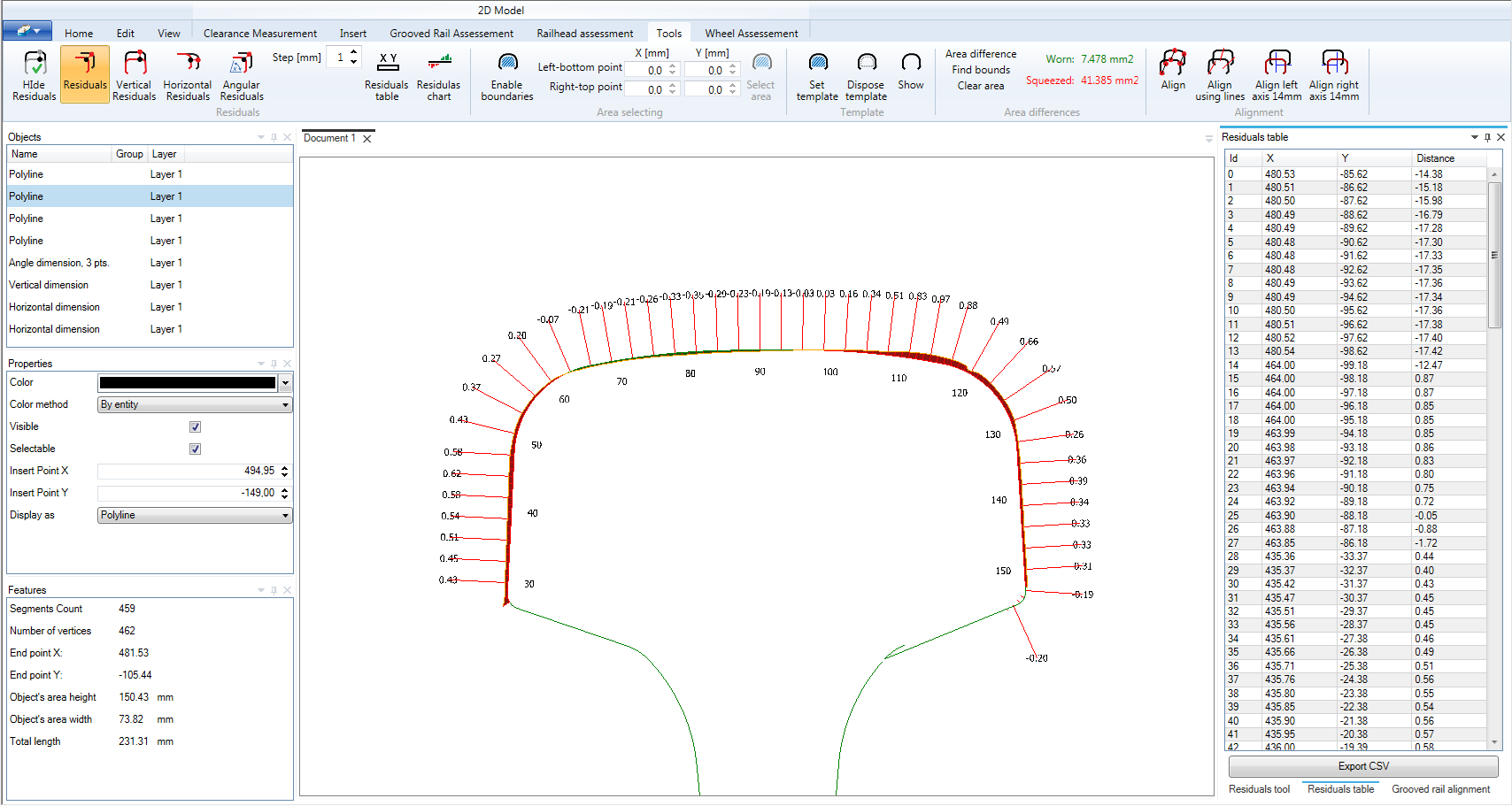

Screenshot of the PC measurement data analysis and reporting software delivered with the trolley

The trolley is supplied with the Dari® software (for PCs) enabling, among other things, the graphic presentation and comparison of measurement results as well as the printing of measurement reports or calculating typical track quality factors. Measurement results are also available in the tabular form containing track defect locations. Measurement data can be exported in MS Word, MS Excel and PDF formats.

In addition, the software enables the saving of measured profiles in the DXF format, comparing measured profiles with model profiles, automatic sizing and printing of rail profile-related reports.

Contents:

- Trackscan Profile trolley with the control panel

- Two sets of batteries + charger

- Charger for the control panel

- Boxes for storing and transporting laser heads

- Transport boxes

- Dari® software for data analysis, 1 licence

Benefits:

- Geolocation of point measurement using GPS

- Quick removal from the track without interrupting the measurement session possible

- Results of visual track inspection can be recorded while measuring

- Hot-swappable batteries – charged batteries at hand enable unlimited operating time

- Measurement results independent of environmental conditions

- The included Dari® software for data analysis allows for additional export of measured data to MS Excel and MS Word, as well as PDF, DXF, CSV formats

Specifications

| Railhead cross sections | Accuracy of mapping ±0.3 mm |

| Track gauge | Accuracy: ±0.5 mm |

| Measurement range: -15 … +50 mm | |

| Cant | Accuracy: ±1.5 mm |

| Measurement range: ±200 mm | |

| Horizontal irregularities | Accuracy: ±0.2 mm / 1 m |

| Measurement range: ±5 mm | |

| Vertical irregularities | Accuracy: ±0.2 mm / 1 m |

| Measurement range: ±2 mm | |

| Calculated parameters | |

| Twist | Accuracy: ±3 mm |

| Gradient | Accuracy: ±1 mm |

| Railhead wear | Accuracy of mapping: ±0.3 mm |

| Railhead wear | Accuracy of mapping ±0.3 mm |

| Measuring increment | 0.25 m |

| Types of rails | Vignol or groove |

| Dimensions (L x H x W) for 1435 mm track | 1 850 x 870 x 1 300 mm |

| Weight (standard version for 1435 mm track) | 37 kg |

| Memory capacity | 3 000 km |

| Operating time | Up to 5 h |

| Resolution | 0.1 mm |

| Operating conditions | Temperature: -20 … +45 °C |

| Humidity: 15 … 85 %, no condensation | |

| Nominal track gauge | 1435 mm, other on request |