The TSC trolley measures track geometry. The measurement

results include values of track gauge, cant, horizontal and vertical irregularities along with the calculated gradient and twist parameters.

Wheel measurement

Back to the listElectronic Wheel Wear Caliper: WWC

FAST, DIGITAL, RELIABLE AND ACCURATE MEASUREMENTS

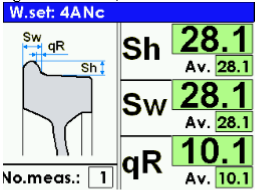

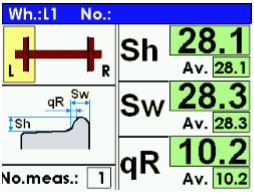

Electronic caliper for railway wheels. The device is designed to measure the parameters Sh, Sw, qR characterizing the wear of rolling stock wheels. Measurements can be performed directly on vehicles, i.e. without rolling the wheelsets out. The user can specify the limit values of the parameters as required.

During measurements, the moving measuring tips touch the measured surface precisely at points specified by the railway regulations. Values of h, e1/e2, and qR parameters appear on the gauge panel display within two seconds after the initiation of the measurement and are clearly visible both in direct sunlight and in a dark inspection pit.

Electronic caliper for railway wheels. The device is designed to measure the parameters Sh, Sw, qR characterizing the wear of rolling stock wheels. Measurements can be performed directly on vehicles, i.e. without rolling the wheelsets out. The user can specify the limit values of the parameters as required.

During measurements, the moving measuring tips touch the measured surface precisely at points specified by the railway regulations. Values of h, e1/e2, and qR parameters appear on the gauge panel display within two seconds after the initiation of the measurement and are clearly visible both in direct sunlight and in a dark inspection pit.

The gauge is equipped with a control panel with colour backlit display, and a comfortable keyboard. Measurement results and information about the exceedings of the limit values are clearly visible even in a dark inspection pit.

Wheel preview measurement Wheelset preview measurement

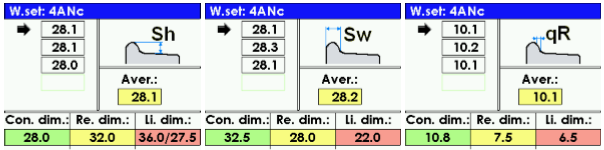

The gauge is delivered with PC software that allows for: archiving of measurement results, comparison of results, as well as printing of measurement reports. Measurement data can be exported to MS Word, MS Excel and PDF formats. The software delivered with the gauge also allows for collecting measurement results from all wheel measurement devices and generating aggregate reports.

Windows with details of measured parameter

Contents:

- Three-Point Wheel Diameter Gauge device

- Chargers

- Transport box

- PC software, 1 licence

Benefits:

- Evaluation of measurement results for wheels sets, bogies and entire wagons

- Measurement results independent of environmental conditions

- Display is easy to read even in direct sunlight

- Easy transfer of measurement data via USB port

- Dedicated software for printing measurement reports, archiving and comparing measurement results

- Simple and solid basing of the device on the wheel

- User-friendly one-man operation

Specifications

| Flange height Sh | Accuracy: ±0.1 mm |

| Flange thickness Sw | Accuracy: ±0.1 mm |

| Flange angle dimension qR | Accuracy: ±0.1 mm |

| Ranges: | |

| Sh | 12.5 … 39 mm |

| Sw | 13 … 30 mm |

| qR | 0 … 27 mm |

| Weight | 1.6 kg |

| Memory capacity | 8 000 measurement files |

| Operating time | Up to 10 h |

| Resolution | 0.1 mm |

| Operating conditions | Temperature: -20 … +45 ºC |

| Humidity: 15 … 85 %, no condensation |